The complete paper demonstrates the application of an interpretable machine-learning work flow using surface drilling data to identify fracable, brittle, and productive rock intervals along horizontal laterals in the Marcellus shale. The results are supported by a thorough model-agnostic interpretation of the input/output relationships to make the model explainable to users. The methodology described here can be generalized to real-time processing of surface drilling data for optimal landing of laterals, placing of fracture stages, optimizing production, and minimizing frac hits.

Modeling Approach

In a multiwell field development, the ability to improve recovery efficiency per rock volume depends on well spacing, stacking, completion strategy, and avoidance of frac hits.

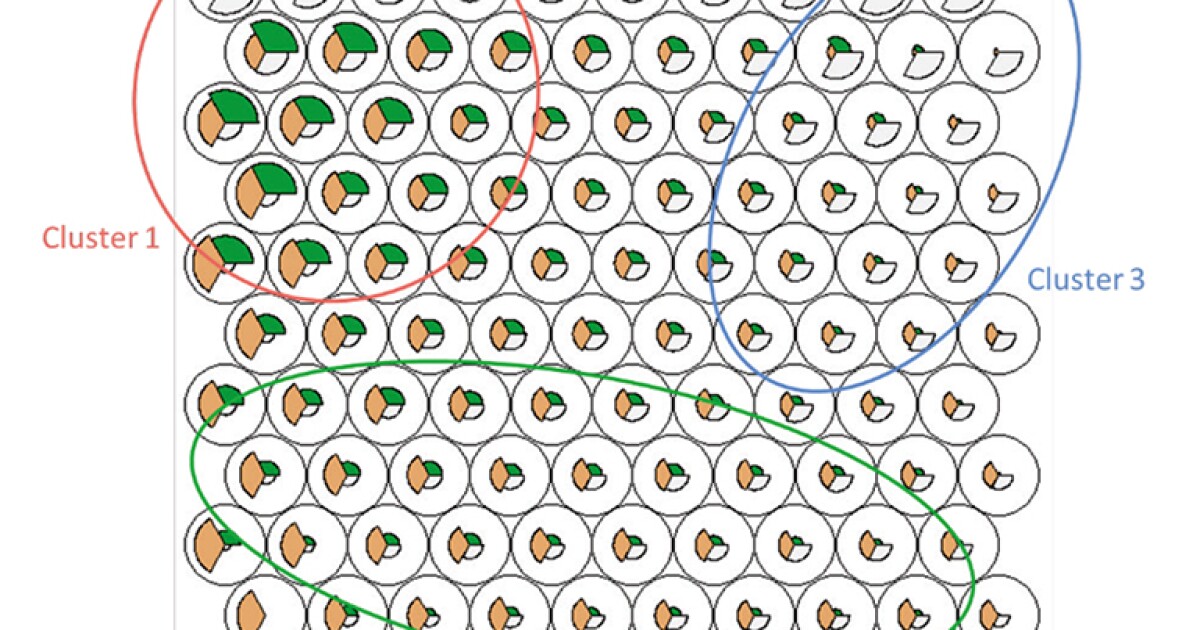

In this study, the authors use surface drilling data to predict mechanical rock facies (generated using Poisson’s ratio and Young’s modulus) using several supervised classification methods. The objective is to use the trained model to predict the mechanical facies in real time using surface drilling data in future wells to optimize the well trajectory and placement of fracture stages.

The highlighted modeling approach is conducted as follows:

- Data preparation.

"machine" - Google News

October 01, 2021 at 12:03PM

https://ift.tt/3uvxvhK

Machine-Learning Work Flow Identifies Brittle, Fracable, Producible Rock Using Drilling Data - Journal of Petroleum Technology

"machine" - Google News

https://ift.tt/2VUJ7uS

https://ift.tt/2SvsFPt

Bagikan Berita Ini

0 Response to "Machine-Learning Work Flow Identifies Brittle, Fracable, Producible Rock Using Drilling Data - Journal of Petroleum Technology"

Post a Comment